The 10-Second Trick For Motorcycle Parts New Zealand Specialists

Table of ContentsAll about Motorcycle Parts New Zealand SpecialistsWhat Does Motorcycle Parts New Zealand Specialists Mean?The smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is Talking AboutThe Motorcycle Parts New Zealand Specialists IdeasMotorcycle Parts New Zealand Specialists for BeginnersMotorcycle Parts New Zealand Specialists Things To Know Before You BuyExamine This Report on Motorcycle Parts New Zealand SpecialistsAn Unbiased View of Motorcycle Parts New Zealand Specialists

So, connect to one of our professionals today.CNC machining modern technology is promptly coming to be the prime focus of several manufacturing procedures around the globe as a direct result of its many advantages over various other approaches. Furthermore, the industries that make bikes have hopped on board with this trend. One of the most cutting-edge firms are now developing their engine components and wheels making use of machining strategies initially established for motorbike components.

You may be wondering why we make use of. Now that we have your interest let us discuss the rationale behind this modern growth in the motorcycle production sector.

A Biased View of Motorcycle Parts New Zealand Specialists

Furthermore, you have full control over the appearance of the components, even to the min details. Occasionally, motorcyclists may decide to beautify their adventure by setting up aftermarket elements or modifying the bike's remodeling. When once again, computer mathematical control (CNC) machining is the most sensible technique. Upgrades may be of any kind of kind and style you desire.

How Motorcycle Parts New Zealand Specialists can Save You Time, Stress, and Money.

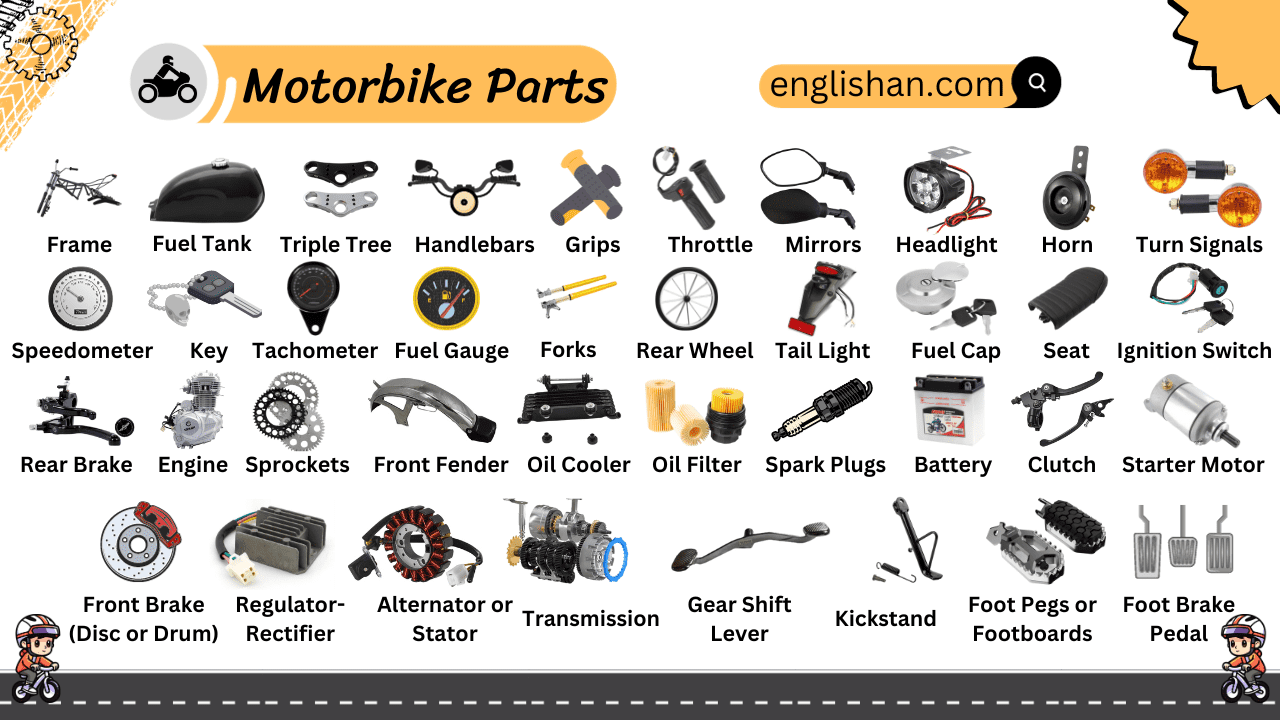

CNC machining may be utilized to make virtually all of a motorcycle's metal and plastic elements. To proceed, we'll discuss several machined parts for bikes. In comparison to those on automobiles, wheels on bikes tend to be much more evident. Because of this, the bike's appearances may be enhanced with the ideal customization of these wheels.

When personalizing the wheels, the disks are where the focus ought to be. Most of them are made out of aluminum. Aluminum alloys are popular for the outstanding machining capabilities that they have. Milling treatments are made use of to get the preferred level of wheel personalization. One more aspect of the motorbike that might be customized is the tires.

About Motorcycle Parts New Zealand Specialists

When it comes to an automobile (or a motorbike), one of the most important element is the engine. Numerous people suggest to it as the "heart" of the vehicle. On the various other hand, the camshaft, the cyndrical tube head, and the pistons have a tendency to be detailed and require designs with a high level of precision.

Lighting is one more facility aspect of personalization. Usage only high-grade items, nonetheless, given that these lights are important for the safety and security of motorcyclists and other chauffeurs or individuals when driving, especially during the night. Motorbike fronts lights have 3 almosts all: the bulb, or source of light, the lens, and the housing. Specifically, we customize the lens and the real estate.

Milling processes with a perfect surface would result in the lenses having a reflective quality that resembles that of a mirror. The cover, on the other hand, is not made up of breakable products; instead, it is constructed out of tough polymers that can be machined right into more complex patterns.

What Does Motorcycle Parts New Zealand Specialists Do?

Motorcycle makers often cast these parts, however only for the manufacturing of bespoke components. Machining on 5 axes in today's globe is the means by which any type of style form may be realized.

Choose Runsom for your customized bike components! We have the ability to produce complicated and stylish components making your motorbike incomparable.

Right here are a few instances of metals usually made use of in bike part machining. Light weight aluminum is the key product utilized by business focusing on creating customized motorcycle components to develop a lot of these components. In the past, we would build our engines out of actors iron. On the various other hand, aluminum is rapidly becoming the product of option, partly directory due to the reality that it is a lot more lightweight.

Zinc describes an additional metal that is very light in weight and has fantastic machining qualities as a result of its high mechanical stamina. This product may be created into almost any kind of form and preserves its dimensions well. Even mission-critical parts that need a high degree of accuracy might take advantage of their use.

Get This Report on Motorcycle Parts New Zealand Specialists

Another metal that sees hefty usage in the production of CNC-customized parts Discover More Here is magnesium. It is among the lightest metals that are now available and has outstanding machinability features and strength proportionate with its reduced weight. One of the drawbacks of magnesium is that its dirt might quickly ignite.

Their most usual use in generating different motorcycle parts is fasteners, such as screws and screws. Their low vulnerability to oxidation and corrosion makes them excellent for this use.

The Greatest Guide To Motorcycle Parts New Zealand Specialists

It appears that CNC turning and milling are the foundational processes. In addition, it requires maintaining bars of product, most commonly plastic or metal, in placement and after that twisting a cutting device to remove areas of the material as the material is transformed.

These approaches are similarly important and produce components with high precision and consistent quality. They are respectively: grinding, laser cutting, and exploration. The term "surface coating" describes post-processes click for info after the initial machining phase. Motorcycle Parts New Zealand Specialists. The processes aid enhance the total high quality of the machined motorcycle elements. Below are the quick introduction, benefits and drawbacks of five surface area treatment techniques.

Get This Report on Motorcycle Parts New Zealand Specialists